Quality

QUALITY CONTROL

All our products are manufactured under stringent quality supervision and testing. The materials are subjected to exhaustive QC measures before being dispatched to our valuable customers. During manufacturing the following steps are undertaken to ensure Quality of the finished product.

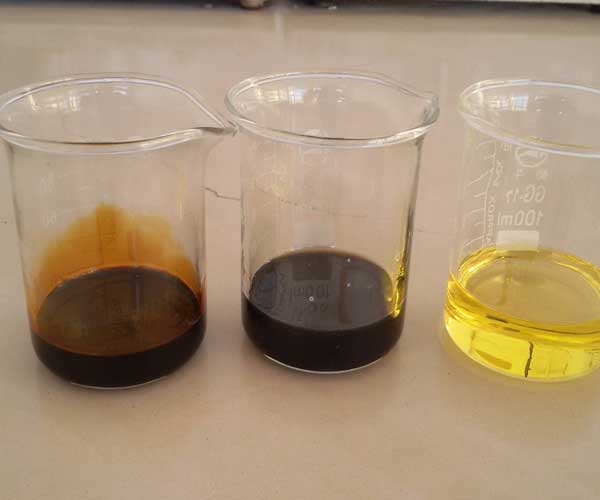

Bleaching Activity

A hard to bleach oil, with known ffa and color is treated with various dosages of Premier Industries Earth under standard vacuum, temperature, contact time and stirring. The colors are measured in Lovibond Tintometer and the results are compared with standard earth results.

Acidic Property

Measurement of residual free acid content as well as pH value of water solution filtered out of the Bleaching Earth are routine test with titration method as well as pH meter and stringent standards are maintained for the same.

Moisture Content

Moisture content is measured in a standard laboratory drying chamber as well as by Karl-Fisher- titrations.

Particle – Size Distribution

It is checked on standard sieves by careful air stream sieving as well as on particle size analyser.

Filtration Property

We have a standard, exhaustive, test method for determining the filteration properties of our bleaching earth. We filter oil under standard conditions of temperature and pressure difference over an oil-wet-filter-cake. Stringent standards are followed and maintained to ensure fast filtration rate of Refoil Earth.